|

|

|

SAND PREPARATION PLANT

A)

B)

C)

D)

E)

F)

G)

H)

I)

L)

M)

|

|

|

|

|

|

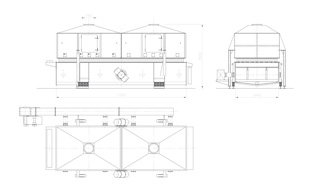

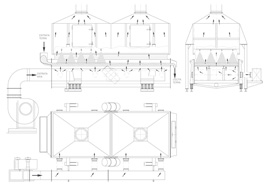

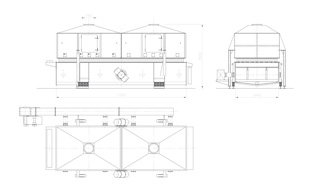

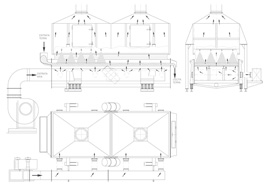

E) FLUID BED SAND COOLER RF

|

RF

|

|

|

| |

|

| |

Type |

RF10 |

RF25 |

RF30 |

RF45 |

RF60 |

RF70 |

RF90 |

RF120 |

RF140 |

RF180 |

| Capacity |

t/ h |

10/15 |

15/25 |

25/35 |

35/50 |

52/60 |

70/82 |

84/100 |

110/130 |

140/164 |

168/200 |

| Exchange surface |

m2 |

3 |

4.3 |

5.9 |

8.5 |

10.8 |

14.4 |

17.5 |

22 |

28.8 |

35 |

| Cooler length |

mm |

5400 |

5400 |

5400 |

5400 |

5400 |

6000 |

7300 |

5400+5400 |

6000+6000 |

7300+7300 |

| Cooler width |

mm |

550 |

800 |

1100 |

1600 |

2000 |

2400 |

2400 |

2000 |

2400 |

2400 |

| Sand speed |

m/h |

200 |

200 |

216 |

216 |

216 |

240 |

292 |

430 |

480 |

584 |

| Holding time |

sec |

98 |

98 |

90 |

90 |

90 |

90 |

90 |

90 |

90 |

90 |

| Sand botton weight |

mm |

100/120 |

100/120 |

100/120 |

100/120 |

100/120 |

100/120 |

100/120 |

100/120 |

100/120 |

100/120 |

| Vibrator power |

kw |

2x2.2 |

2x3 |

2x3 |

2x4 |

2x6 |

2x6 |

2x8 |

4x8 |

4x8 |

4x10 |

| Blowing ventilator capacity |

m3/h |

4000 |

5200 |

6000 |

11000 |

14000 |

18000 |

23000 |

28000 |

36000 |

46000 |

| Pressure |

mmH2O |

200/220 |

200/220 |

200/220 |

200/220 |

200/220 |

200/220 |

200/220 |

200/220 |

200/220 |

200/220 |

| Ventilator power |

kW |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

30 |

37 |

45 |

55 |

| Air volume to be aspirated |

m3/h |

5000 |

6800 |

9000 |

16000 |

22000 |

27000 |

34000 |

44000 |

54000 |

68000 |

| Required depression at the mozzles |

mmH2O |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

| |

|

|

|

MEC MASTER srl

Via degli Artigiani, 8 - 31035 Crocetta del Montello (Treviso) - ITALIA

Tel 0039 0423 639369 Fax 0039 0423 638081

Part. IVA 01244680268

info@mecmaster.com

|

|

|